Written by

Petra Pavlovic

Marketing and Communications Director

In rail, reliability is everything. But behind that reliability lies something less visible – the ability to experiment, adapt, and evolve quickly. At KONUX, that’s exactly what drives our approach to hardware innovation and defines how we build the technology that keeps networks moving.

Engineering at the Speed of Insight

Our IoT devices are more than sensors – they’re field-proven instruments built to thrive in demanding environments. But the real differentiator is how fast we can turn an idea into a fully operational product that meets rigorous rail standards.

Through an agile, end-to-end development process, our engineering and device teams can move from concept or prototype to certified hardware in record time. Every iteration builds on operational feedback, data insights, and lessons from the field, ensuring that each new generation is smarter, lighter, and more efficient than the last.

From Field Insights to Hardware Evolution

The best innovations often emerge not from the lab, but from the trackside. Our close collaboration with rail operators gives us direct visibility into how devices perform in live conditions – what endures, what can be optimized, and where design can unlock even greater resilience. Every deployment is a learning opportunity, revealing where durability, design, or data capture can be improved.

That’s how KONUX Connect 2.0 came to life.

It’s the latest evolution of our KONUX Switch IoT device – more compact and easier than ever to install. The device still operates fully autonomously and maintenance-free for years, capturing data from every passing train together with temperature, geolocation, and timestamps.

Designed for long-term reliability, KONUX Connect 2.0 combines enhanced LTE-M connectivity, configurable data transmission, and an integrated temperature alarm to deliver uninterrupted insights and stronger network visibility. Installation takes less than ten minutes, mounting directly on existing sleepers without any infrastructure changes.

Each detail, from edge computing and remote configuration to new improved flexibility, reflects an iterative design philosophy grounded in real operational feedback.

Building Better, Faster

What makes this evolution significant is the hardware improvements and most importantly speed and precision of how they were achieved.

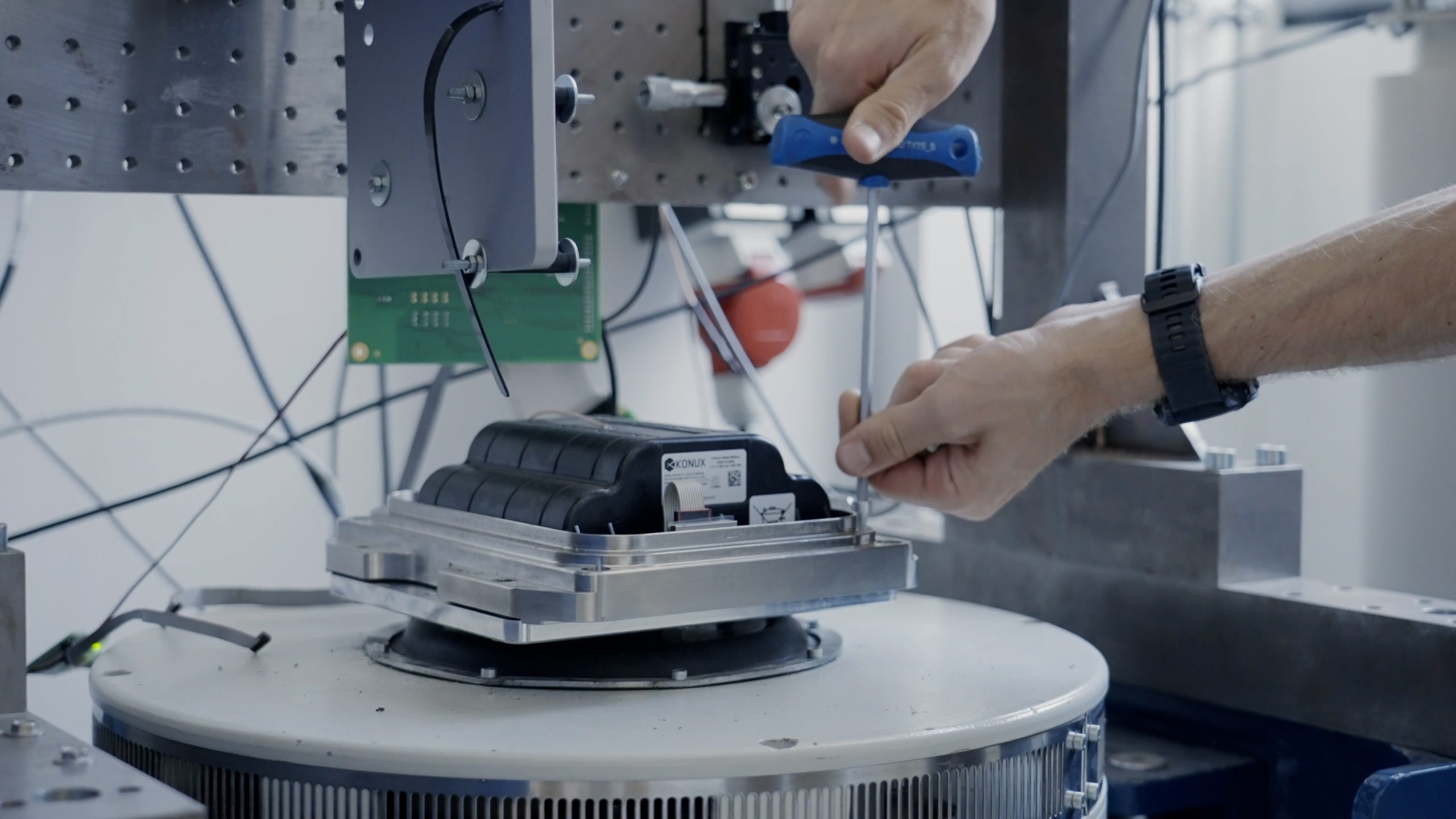

By integrating mechanical design, connectivity engineering, inhouse and field testing in parallel, KONUX has built a development pipeline that can adapt to the complex requirements of railway infrastructure without compromising certification or safety.

Every new prototype is tested, verified, and validated in the same conditions it will later operate in, ensuring the leap from idea to deployment is as efficient as possible. This approach accelerates innovation and ensures that each new device and device generation is ready to perform from day one. This agile engineering framework makes KONUX uniquely capable of adapting to customer needs and industry shifts – delivering reliable, connected infrastructure faster.

A Continuous Cycle of Innovation

KONUX’s mission has always been to make rail infrastructure smarter, faster, and more reliable. Rapid IoT prototyping is one of the quiet enablers of that mission – a process that ensures our solutions evolve at the pace of our customers’ challenges.

KONUX Connect 2.0 is only one expression of this agility: built through close collaboration, designed for long-term reliability, and engineered to keep networks running safely and efficiently.

In rail, innovation is not a one-time event – but it does happen faster when you build the right systems for it.

Written by

Petra Pavlovic

Marketing and Communications Director