Written by

Nikhitha Rallabandi

Junior Data Scientist

Lukas Bernhard

Engineering Manager Signalling

Petra Pavlovic

Marketing and Communications Director

Static Thresholds Assume Stability

Traditional Point Machine (PM) monitoring relies on fixed thresholds, such as maximum motor current, movement time, or vibration, to decide whether the machine is behaving normally or requires attention. This method assumes that the machine’s operating behaviour remains stable over time. In reality, PMs are exposed to constantly changing outdoor conditions. PMs operate in some of the harshest and dirtiest environments in rail infrastructure. Interestingly, weather is one of the most significant external influences affecting their performance, reliability and overall lifetime. Because of this, the same machine may show very different electrical current profiles or movement durations under different weather conditions, even when nothing is mechanically wrong.

Weather conditions such as rain, snow, drastic temperature changes, and humidity directly affect the physical environment around the point section and the machines itself. Therefore most railway networks have seasonal adjustment days – specific times during the year when maintenance teams tune or adjust components of the PM infrastructure to prepare for the coming season. These adjustments are necessary because environmental conditions change dramatically across seasons.

Weather Introduces Variability

Weather-driven effects create extra variability in how the PM behaves. Each weather type influences the machine in a different way:

- Temperature Variations – thermal expansion, or contraction of parts, lubricants can get dry or thicken.

- Rain and Humidity – corrosion of joints and connectors, flooding washes away of lubricants and damages motor.

- Snow and Ice – can compact and obstruct the switch, requiring more current or force, frozen ballast restricts drainage, leading to flooding when thawed, ice can block the movement of rods or switch blades.

- Wind and Debris – blows sand, dust, or debris into mechanisms, increasing contamination, push tree branches or objects that obstruct point movement.

This variability is behaviour is problematic.

Seasonal Behaviour Requires Expert Interpretation

PMs naturally behave differently in winter vs. summer, even without any mechanical issues. If weather effects are not accounted for, these seasonal variations can look like early signs of degradation. Weather conditions can temporarily change electric current draw or movement time, leading to false alerts when interpreted without environmental context. A machine may look “worse” simply because the environment is harsher at certain times of the year not because the asset has actually deteriorated.

Environmental Stress Can Trigger Real Mechanical Issues

On the other hand, weather does not only introduce noise, it can directly cause failures. For example:

- Ice or snow physically blocking movement

- Rain washes away lubrication which leads to more friction and stress on the PM

- High temperatures accelerating wear on the switch and PM as material is expanding

The example below shows how weather, in the form of a temperature change, can affect a PM. Both movements (or throws) are only one day apart, the only difference is that one movement took place at around 16.5C and the other 9.8°C. A temperature decrease of 38% within a short amount of time put a lot of stress on the machine.

The Threshold Dilemma of Sensitivity vs. Noise

Fixed thresholds treat any value above a set limit as problematic, but “normal” is not a single value, it varies with the environment. A single threshold cannot distinguish between a machine operating under harsh conditions and one that is slowly declining under ideal conditions, making this approach too simplistic for real-world use.

Setting higher thresholds to avoid weather-driven alerts makes the system insensitive to early signs of change. Slight increases in current or movement time (often the first indications that something is starting to drift) go unnoticed. Only severe deviations would trigger alerts and attention, leading to late detection and potential unexpected breakdowns. In a railway environment where reliability and punctuality are essential, missing these early signals can result in service disruptions and costly emergency interventions.

Conversely, a low threshold to catch subtle deviations introduces the opposite issue. Cold temperatures, heavy rain, or snow can easily push measurements above a low limit, even when the machine is behaving as expected for those conditions. This results in numerous false alerts, forcing operators to investigate issues caused entirely by the environment. Over time, this creates alert fatigue, wastes maintenance resources, and reduces confidence in the PM monitoring system.

Operators are therefore stuck with a trade-off: set thresholds high and risk overlooking important changes, or set them low and face an overwhelming number of unnecessary alerts. This fundamental trade-off shows why static thresholding cannot cope with a dynamic, weather-dependent environment.

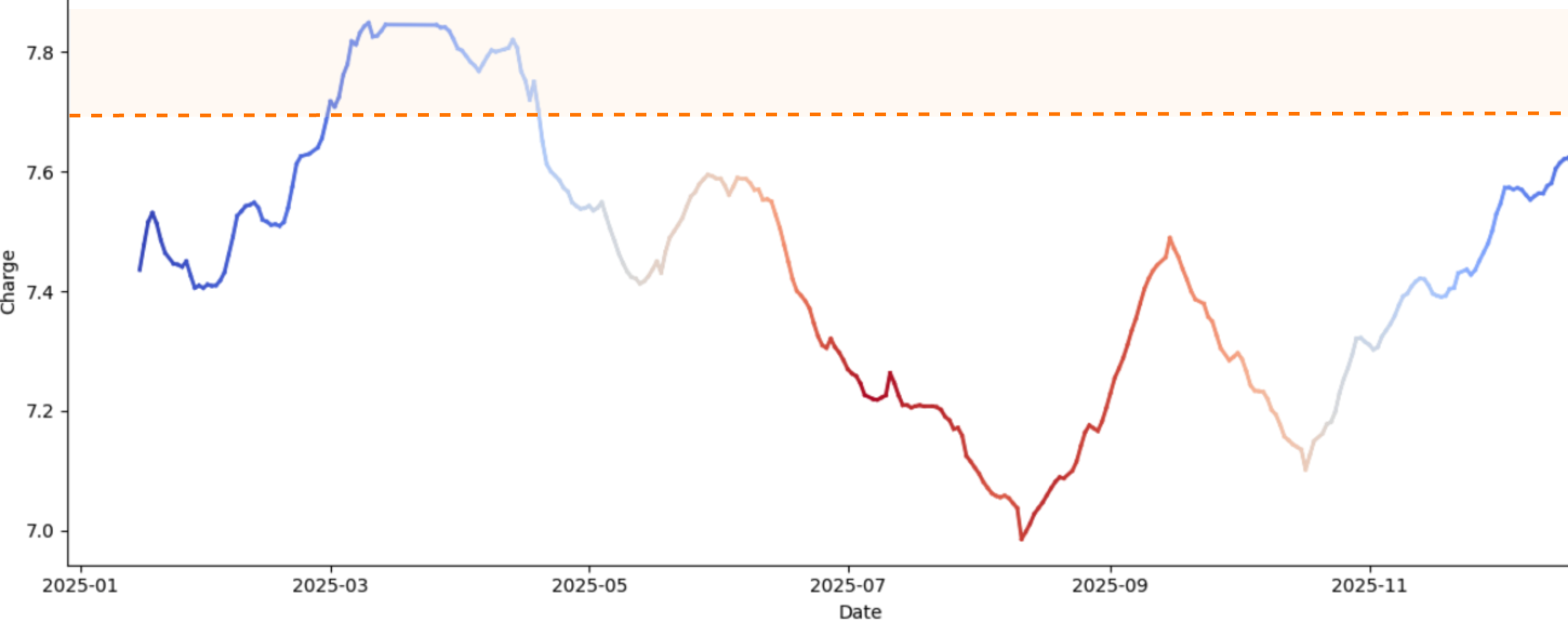

The example below shows the electrical charge of a machine coloured by temperature over a whole year. We can see that for this PM, low temperature (blue) results in higher energy consumption compared to higher temperature (red) resulting in lower energy consumption. With the added threshold (orange), it becomes clear that in summer receiving an alert before failure of the machine is very unlikely as the low charge in summer leaves significant room towards the threshold.

Accounting for the Environment with Weather Aware Alerts

KONUX Switch addresses the limitations by understanding how each point machine normally behaves under different weather conditions. Instead of assuming one static “normal,” our solution analyses how temperature, rain, snow, and seasonal variations naturally affect signals such as current and movement time. Our models also learn and compare measurements with other machines to identify shared patterns and highlight anything unusual. This dual perspective – individual behaviour plus fleet-wide comparison – gives a much clearer picture of what is expected under specific weather conditions.

From this understanding, our solution calculates how much of the PM’s behaviour is influenced purely by weather, which allows us to establish weather-adjusted expectations rather than rigid thresholds. Instead of sending an alert to operators whenever a weather-driven change occurs, KONUX Switch compares measurements to what is appropriate for that specific environment. This allows the solution to set smarter thresholds that change depending on conditions which results in more precise alerts. Unnecessary alerts caused by weather are significantly reduced, deviations that cannot be explained by the environment become easier to detect. This leads to clearer, more reliable alerts and far fewer false positives.

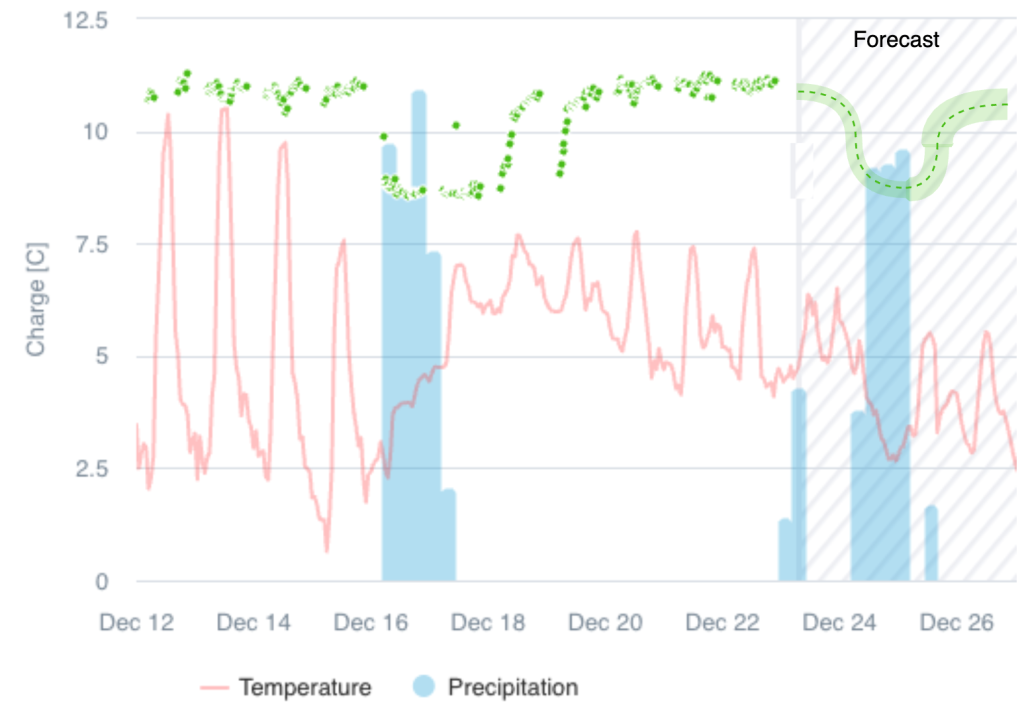

Using Weather Forecasts to Anticipate Behaviour

Now that our solution understands the weather influence on the machines, it can use weather forecasts to anticipate how machine behaviour is likely to change in the coming days. If a temperature drop or heavy rain is expected, operators can understand in advance how this will influence upcoming measurements. This proactive awareness prevents unnecessary investigations and helps teams focus on changes that truly stand out from expected weather effects.

Written by

Nikhitha Rallabandi

Junior Data Scientist

Lukas Bernhard

Engineering Manager Signalling

Petra Pavlovic

Marketing and Communications Director