Written by

Petra Pavlovic

Marketing and Communications Director

The KONUX and One Big Circle (OBC) partnership is about rethinking how we see and act on infrastructure health.

For years, the railway industry has talked about predictive maintenance. But the real challenge has not been aspiration, it’s been operationalising it. Making it real for engineers who have to make daily decisions about what needs attention, when, and why.

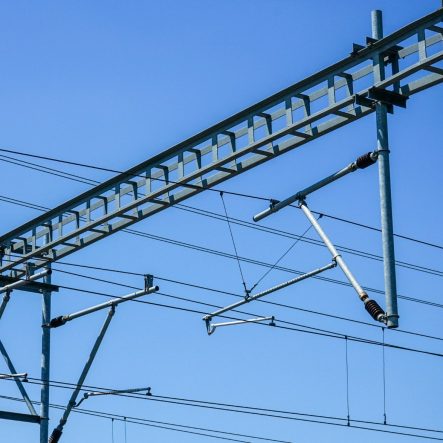

As railway infrastructure continues to face growing pressure from increasing passenger volumes to aging assets rail operators are calling for smarter, more proactive maintenance approaches. We believe data and AI must be at the heart of this transformation. And with OBC as a trusted partner, we’re making that future a reality. We have successfully combined the depth of predictive analytics with the clarity of intelligent video to reshape how switches and crossings (S&C) are monitored, understood, and maintained.

From Siloed Systems to Shared Intelligence

Traditional asset monitoring tools generate data. So too do visual inspections. But when those streams exist in silos, in separate interfaces, disconnected timelines, and misaligned coordinates, the opportunity for further added value is lost.

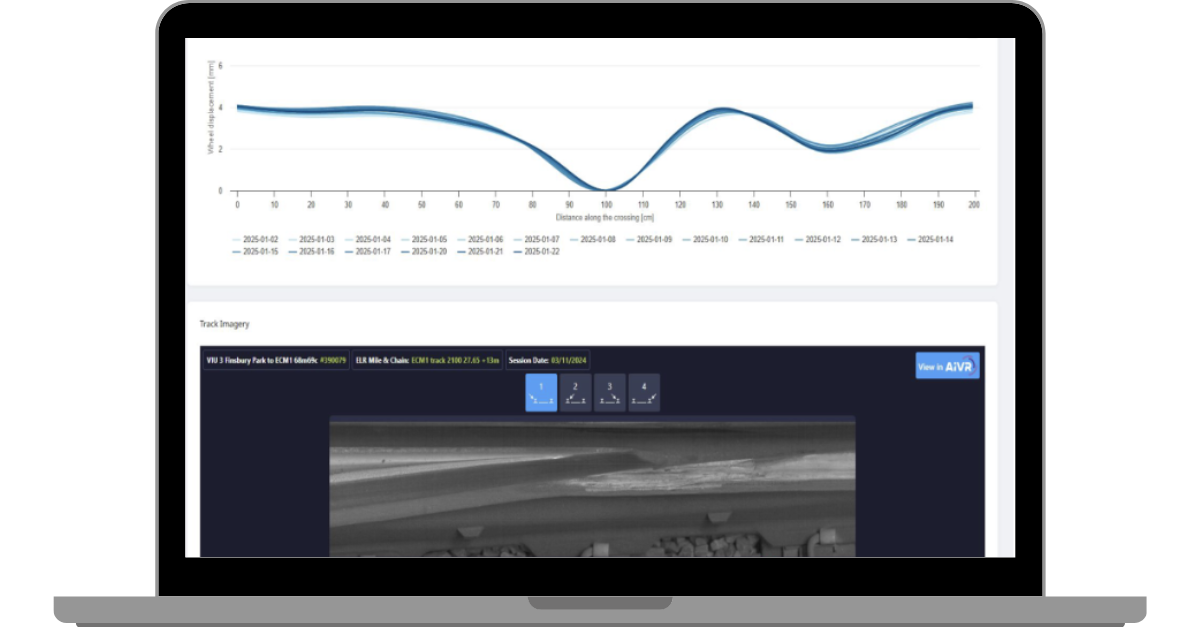

In 2024, we began integrating OBC’s AiVR visual inspection system with the KONUX Switch solution. By embedding AiVR’s line-scan imagery directly into the KONUX Switch platform, and vice versa, we’ve enabled engineers to see health metrics, wheel trajectory anomalies, and physical degradation side by side. In one view. In one workflow. This is not only an integration, it is in fact a convergence. And it matters because the infrastructure challenges we face – from accelerating wear on S&C to reducing workforce risk – cannot be solved by more data alone. They require usable intelligence.

The result of our partnership? Frontline teams can now verify degradation trends visually, correlate anomalies with actual conditions on the track, and reduce reliance on physical site inspections. It’s a significant move towards faster, safer, and more informed decision-making.

Ground-Level Impact: Boots off Ballast, Eyes on Insight

Railway maintenance has historically relied on visual inspections conducted in low-visibility conditions and limited possession windows. Our joint solution changes that. Engineers can now review real-time insights and visual footage from their desks, significantly reducing boots-on-ballast hours and improving workforce safety. The most powerful maintenance decision is the one you make before something breaks. But to act early, you need certainty. And certainty comes from two things: data fidelity and contextual clarity.

That’s exactly what this partnership delivers:

- AI-powered trajectory models that highlight abnormal wheel-rail dynamics over time

- High-resolution imagery that validates the cause

- Time-stamped, georeferenced alignment so there’s no guesswork about location or relevance

As one Network Rail engineer put it, the system “gives us the vital contextual information to understand root cause, scope work remotely, and deliver a right-first-time intervention.” That’s not a feature; that’s a step-change.

Built with the Frontline in Mind

This collaboration did not happen in a lab. It was shaped through joint pilots with Network Rail’s Sussex route, co-design sessions, and continuous feedback from field engineers. Every design decision – from interface layout to platform transitions – was made to serve real-world workflows.

This partnership has already shown operational benefits on the Sussex route, where Network Rail teams now access both data streams via a shared UI. Engineers use KONUX’s Wheel Trajectory Reconstruction (WTR) feature to detect patterns in wheel-rail dynamics, then immediately cross-reference them with line-scanning footage from AiVR. It’s a new level of diagnostic clarity and it’s driving measurable improvements.

The result: engineers now operate with a fused view of condition and context, without toggling across tools or waiting for disparate reports. They’re detecting faults earlier, scoping interventions faster, and spending less time on-track.

Closing the Confidence Gap: From Insight to Intervention

This partnership has not been about layering one system on top of another. From the outset, we’ve worked closely with Network Rail to address real operational challenges:

- Workflow integration:Engineers move effortlessly between platforms, using one interface to interpret both sensor data and video.

- Data alignment:Locational precision ensures that footage and alerts match down to the meter.

- Coverage gaps:With both KONUX and OBC expanding into new routes, data availability is improving rapidly.

KONUX are also exploring deeper integration with Network Rail’s systems including FMS,RDMS and Insight, building toward a more connected and predictive infrastructure.

What Comes Next: Scale, Speed, and Smarter Infrastructure

This partnership is more than a technology overlay; it’s a model for how digital collaboration can accelerate infrastructure innovation. Looking ahead into 2025, our focus is threefold:

- Route Expansion: We’re scaling beyond the South East and East Coast routes to bring our integrated solution to more teams.

- System Interoperability: We’re deepening integration with core systems to streamline alerts and data flow.

- Real-Time Triage: We’re enabling Intelligent Infrastructure Technicians (IITs) and front line engineers to act faster by combining AI alerts with contextual visuals.

And we’re not doing this in isolation. The strength of this partnership lies in its cross-disciplinary DNA – AI engineers, video specialists, railway veterans, and operations leaders – building a system that’s not only innovative but truly usable. As AI continues to mature, the power of combining data intelligence with visual validation will only grow. Together with OBC, we’re creating an ecosystem where data does not only inform but it empowers.

Quote

Integrating the images from AiVR with the insights from KONUX is invaluable, as it gives us vital contextual information to help us understand root cause enabling us to scope work remotely, reducing boots on ballast and helping us to deliver a right first time intervention

Written by

Petra Pavlovic

Marketing and Communications Director