A rail operator, and customer of ours, operates roughly 600 point machines (PMs) that are considered critical to safe, punctual railway operations. Industry experience and research show that a large share of switch-related failures originate in the PM. Nearly 60% of switch delays are due to PM failures, so ensuring their reliable operation is central to network performance. KONUX Switch continuously monitors PM behaviour to detect degradations such as tightlock build‑ups or friction faults from the electrical current of each throw.

The challenge

The operator’s current maintenance regime requires site visits to PMs at least every 12 weeks to ensure compliance and avoid disruption. While well‑intentioned, such cycles often correct potential failures before they fully develop leading to unnecessary, low‑value interventions. In the first half of 2025, our analysis showed that only about a quarter of interventions delivered measurable improvement, and fewer than 40% of maintained machines showed any effective intervention at all. In short: maintenance effort outweighed measurable benefit.

The solution

Step 1: Make degradation visible (diagnostics)

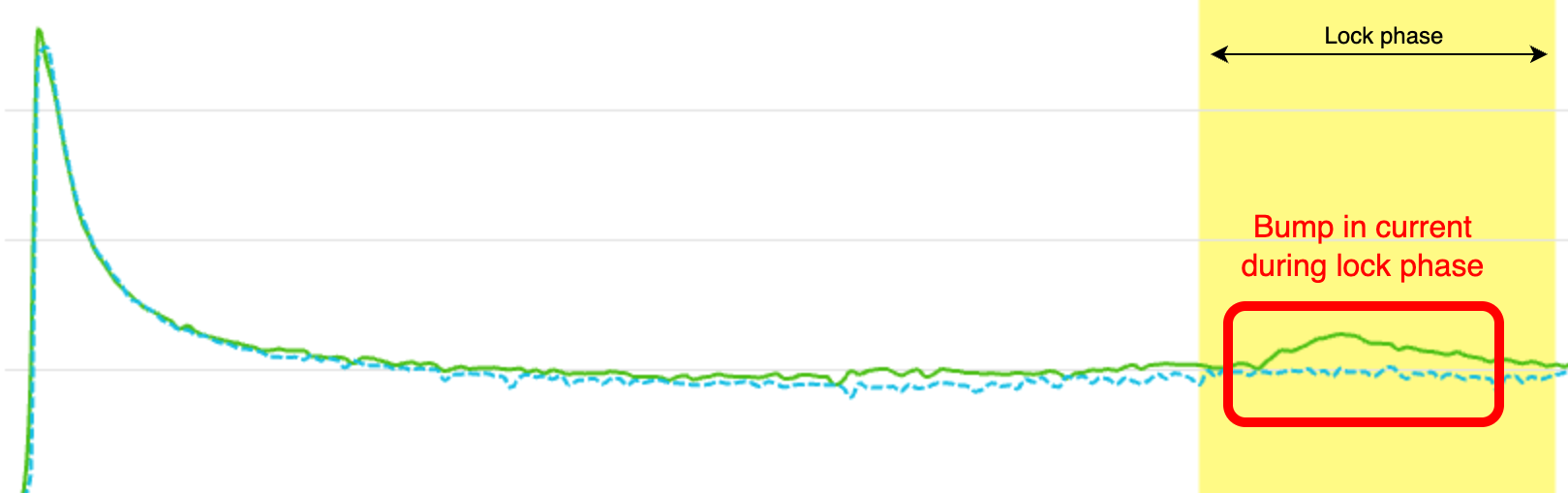

KONUX Switch continuously analyses electrical current of these machines for any signs of failure. The system uses industry knowledge to classify the degradation type (e.g. tightlock failures) and assess severity.

It leverages insights gathered across similar machines in the fleet to continuously improve detection and prediction, while preserving each asset’s unique operational history, condition, and lifecycle.

Step 2 : Give outlook on operational stability (reliability)

To move beyond detection, KONUX Switch incorporates multiple dimensions of information:

- each asset’s degradation trend and historical performance

- type and impact of previous maintenance actions

- condition of the surrounding trackbed

- relevant weather influences

- typical behaviours of comparable machine types

By combining these perspectives, the system provides a holistic clear reliability outlook for every point machine over the coming week.

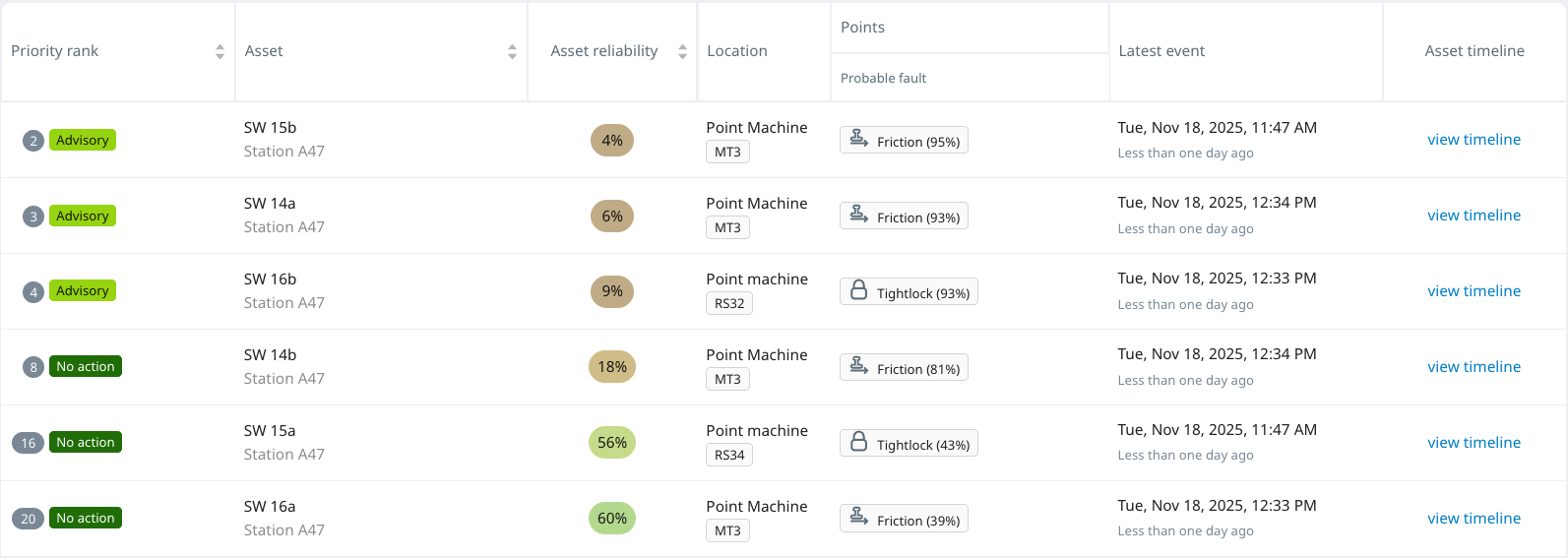

Step 3: Optimising Maintenance Efforts (recommendation)

Once reliability outlooks are established, KONUX Switch prioritises and recommends actions where maintenance will deliver the greatest reliability impact. This targeted approach ensures that maintenance is performed exactly where it is needed most, maximising engineering time and minimising low-value tasks.

By focusing on the assets that truly require attention, the system not only increases the effectiveness of maintenance activities but also significantly reduces the number of unnecessary interventions. This leads to fewer disruptions, optimised workforce planning, and higher network availability

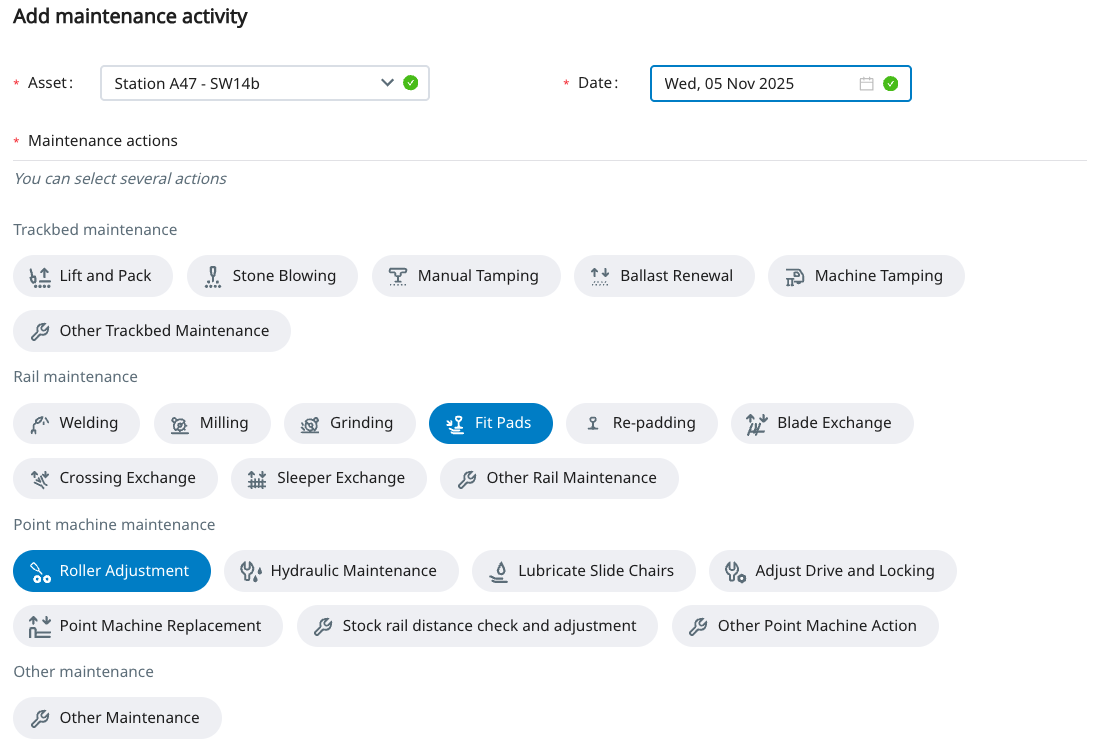

Step 4: Close the loop (collaboration & quality)

KONUX Switch introduces lightweight workflows designed to keep users in control while ensuring seamless collaboration with the system. Engineers can confirm or adjust detected maintenance recommendations, provide feedback on identified issues, and record the actions taken during maintenance activities.

These interactions serve two purposes: they empower users to actively shape and validate the decision-making process, and they enable the system to continuously learn from expert input. Captured feedback improves failure pattern detection precision, reduces false alarms, and refines reliability forecasts – turning the system into a trusted assistant rather than a black box. In this way, the system acts as a supportive partner – enhancing operational efficiency while keeping the final authority with the user.

Results

In the first half of 2025, the operator carried out maintenance across 63 monitored PMs, performing over 150 interventions. The analysis showed that only one in four interventions led to a measurable improvement in machine condition.

This indicates that the majority of activities delivered limited or no impact, suggesting that most work was unnecessary or did not address the underlying issue – IE either addressing the wrong component or occurring too early. Part of this effort may also have focused on nearby assets such as switches, appearing “ineffective” in the point machine data.

These findings reveal a key opportunity: by linking detected degradation, performed maintenance, and measured outcome, the operator can identify which actions truly add value. A data-driven recommendation system based on real reliability impact will enable targeted interventions, reduce wasted effort, and prove maintenance effectiveness with data.

Conclusion

Traditional calendar-based maintenance kept the operator compliant but masked how often visits failed to improve reliability. By instrumenting PMs, detecting degradations early, and measuring intervention outcomes, KONUX and the operator uncovered that many visits brought little benefit. The KONUX reliability estimation and maintenance recommendations turn these insights into action – shifting from “visit every 12 weeks” to “visit where it matters this week.” The result: fewer unnecessary interventions, better resource allocation, and higher network availability.

Written by

Lukas Bernhard

Engineering Manager Signalling

Petra Pavlovic

Marketing and Communications Director