Agon Shporta

Digital Marketing Manager

Keeping trains running reliably on one of the world’s busiest rail networks means preventing small issues from escalating into major disruptions. Network Rail, the organisation responsible for managing this vast infrastructure, oversees the maintenance and performance of thousands of critical assets across the UK. On the Wales Route, a high-traffic crossing began to show early signs of degradation that routine inspections could not explain. With repairs becoming frequent and the risk of service disruptions rising, Network Rail needed a way to uncover the hidden root cause of the problem and move from reactive repair to proactive maintenance.

The Challenge

A high-traffic, critical crossing on the Wales Route showed surface degradation and repeated premature wear, yet routine inspections could not pinpoint a Root Cause. Engineers suspected that trains were losing contact with the rail at a critical point, a phenomenon known as loss of contact force, where wheels lift momentarily before striking back down. Such irregular forces can quickly multiply damage, leading to squat defects, which are cracks and deformations in the rail surface that grow under repeated stress.

Managing such defects was becoming increasingly disruptive for the Wales Route team. Frequent repairs drained resources and budgets, while the risk of escalation carried serious operational consequences. Left unchecked, the defects often trigger Emergency Speed Restrictions or Temporary Speed Restrictions, which protect safety but cause significant delays across the network. Without a way to confirm the suspected wheel–rail behaviour, the maintenance strategy had little choice but to remain reactive.

The Solution

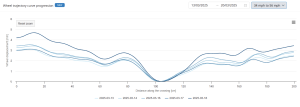

As routine inspections could not confirm the suspected wheel–rail behaviour, Network Rail turned to the KONUX Switch solution to gain deeper visibility into how the crossing was performing. A key feature that proved decisive, was Wheel Trajectory Reconstruction (WTR). WTR was designed to capture wheel–rail behaviour under real operating conditions by reconstructing wheel trajectories and measuring impact force as trains pass over the crossing. Unlike visual inspections or static geometry measurements, which provide only snapshots of surface condition, WTR reconstructs the actual movement of wheels over the crossing and the forces they generate. Devices installed near the crossing in question record data from every passing train, which was then processed through a physics-based digital twin of the crossing. This model allowed engineers to see the vertical path of the wheel, the points where contact is lost and the impact force when the wheel re-engages.

By combining these dynamic insights with 3D laser scans of the track geometry, engineers were able to compare:

- Static dip angles – measurements of rail geometry captured during scanning.

- Dynamic dip angles – the same points measured under actual train loads.

WTR also measured relative acceleration, capturing sudden vertical force changes on the crossing. These metrics, unavailable through routine inspection, gave engineers a new way to understand the stresses acting on the asset.

The Results

WTR allowed Network Rail to see, for the first time, how the crossing was behaving under load. The reconstructed trajectories showed that wheels were lifting briefly at a specific point and then reapplying force suddenly. This repeated lift-off and impact explained the accelerated wear that had puzzled engineers for so long.

At the defect location, the dynamic dip angle was nearly double the static scan figure, and relative impact force was measured at +181% – meaning wheels were striking the crossing with almost twice the expected vertical force after losing contact. In practical terms, this revealed why surface damage was developing so quickly: the additional force was driving cracks and deformations to grow faster than expected, resulting in premature squat defects, shortening the overall lifespan of the asset.

WTR data, when combined with 3D laser scans and geometry surveys, also revealed the underlying cause of this behaviour. Further investigation linked the problem to underlying track geometry issues, which included:

- Poor top faults – irregularities in the vertical alignment of the rail that cause wheels to bounce.

- Gauge variance – small inconsistencies in the distance between the rails that destabilize wheel guidance.

- A dipped insulated joint – a special section of rail used to separate signalling circuits, which had sunk slightly below the surrounding track and created an uneven wheel path.

This clear evidence allowed Network Rail to explain the accelerated wear and identify the crossing as a higher-risk component. Instead of reacting to visible wear, teams began using KONUX Switch to anticipate deterioration and prioritise interventions based on risk. This marked a clear shift in practice: engineers were no longer repairing the same defects repeatedly, but using data to understand why they were happening and preventing them from reoccurring.

Quote

"WTR allowed us to see the full picture. Without it, we would have continued to miss a key failure point."

Written by

Agon Shporta

Digital Marketing Manager

Gary Thompson

Senior Solution Engineer