Introduction

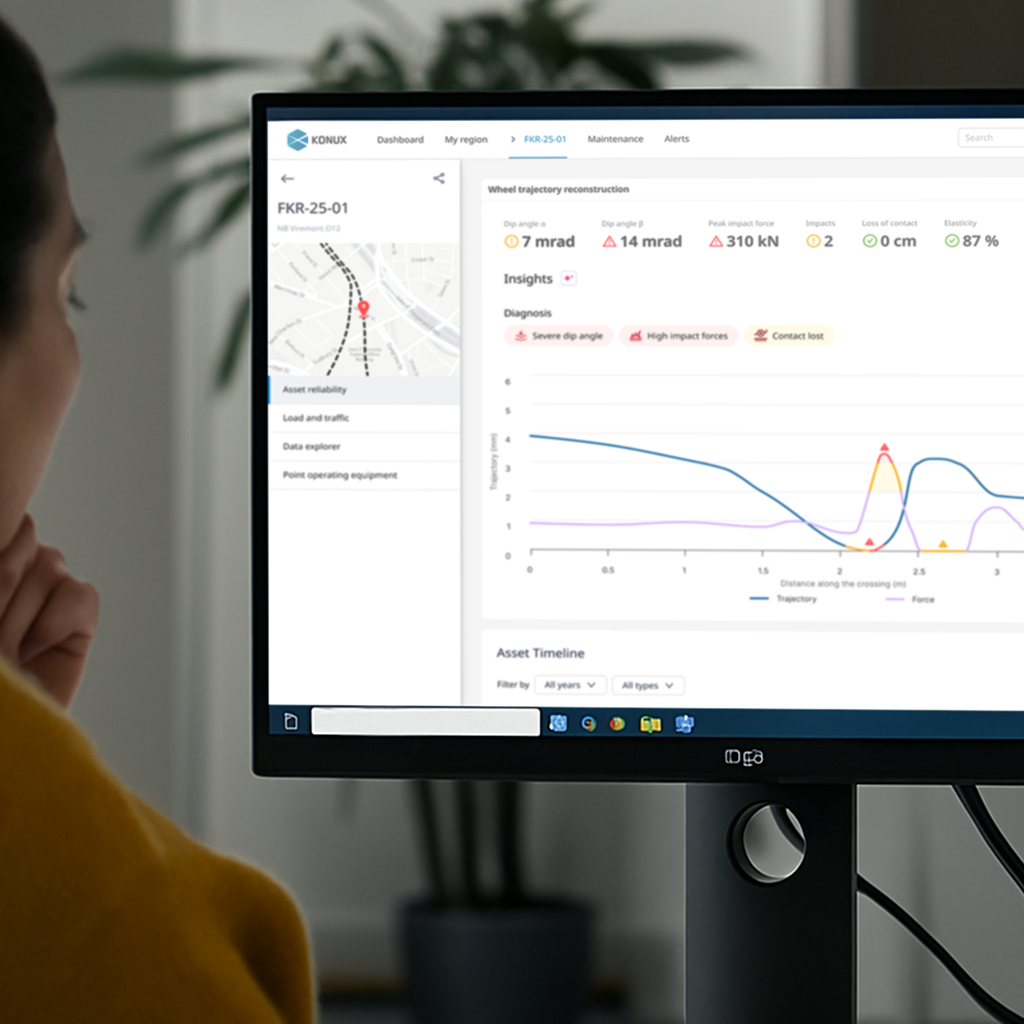

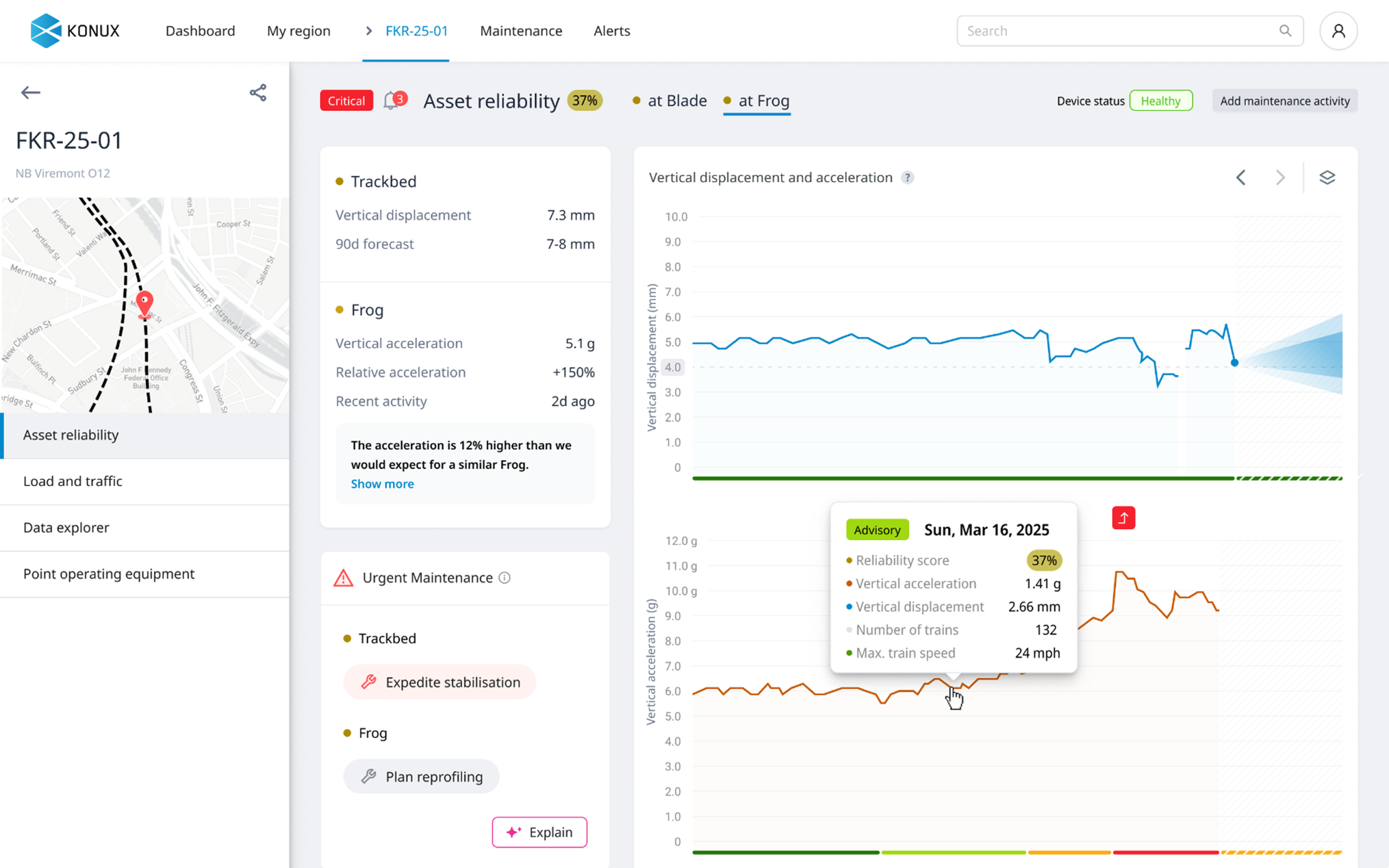

KONUX Switch is a predictive and prescriptive maintenance solution built for the most failure-prone and costly assets in rail infrastructure.

By combining IloT devices, AI, and deep rail expertise, it enables early failure detection, precise diagnostics, and data-driven planning. The result: fewer disruptions, lower OPEX, and longer asset life.

What It Does

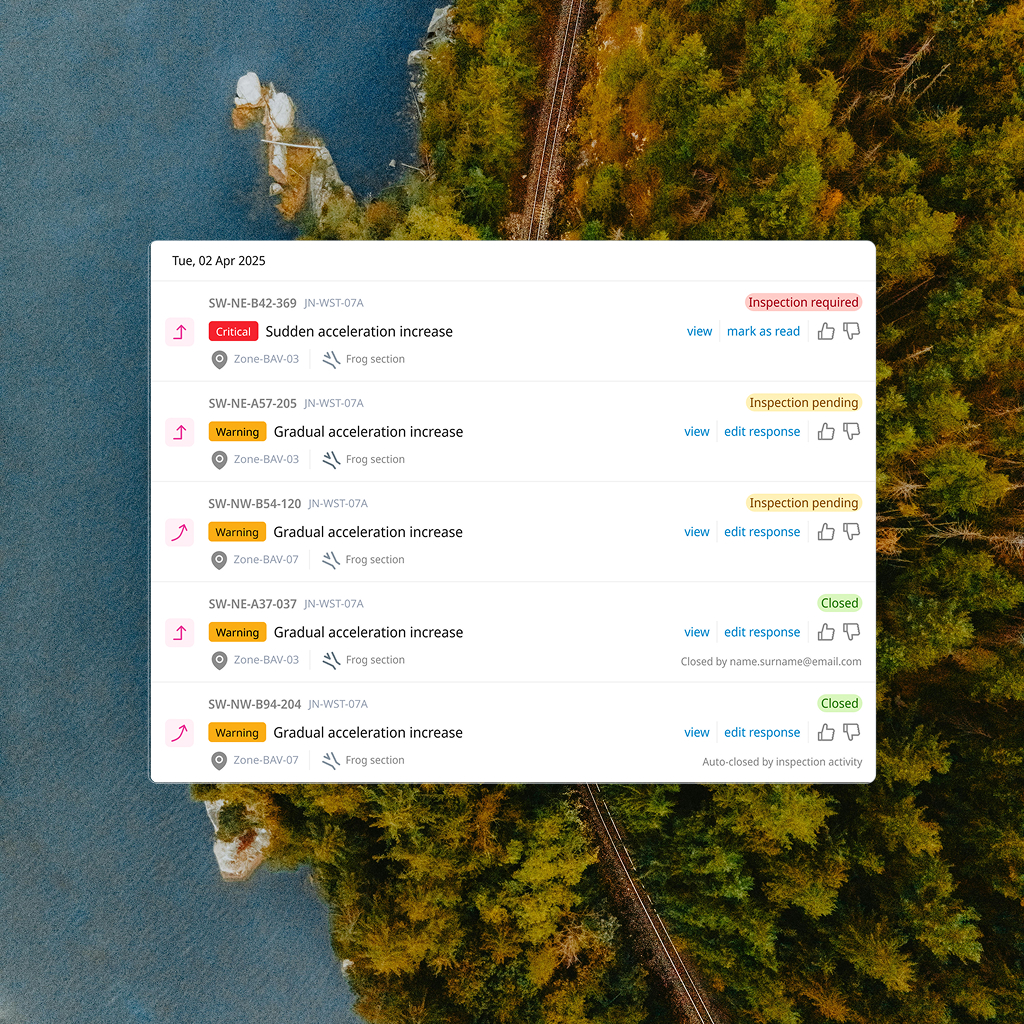

KONUX Switch continuously analyzes the condition of your most critical components, trackbed, frog (crossing), and point machine, providing early alerts and actionable recommendations.

- Detect anomalies before they escalate

- Optimize inspection and maintenance schedules

- Track the effectiveness of maintenance actions

- Extend component life through smarter planning

Use Cases

Maintenance Decision Support & Quality Assessment

Maintenance Decision Support & Quality Assessment

Provides data-driven maintenance recommendations to guide optimal timing and method selection, helping prioritise the most effective interventions. Evaluates the impact of tamping, grinding, or welding by comparing pre- and post-maintenance health states. Helps identify ineffective processes and the root causes of recurring inefficient maintenance activities.

Watch videoFrog Health Monitoring

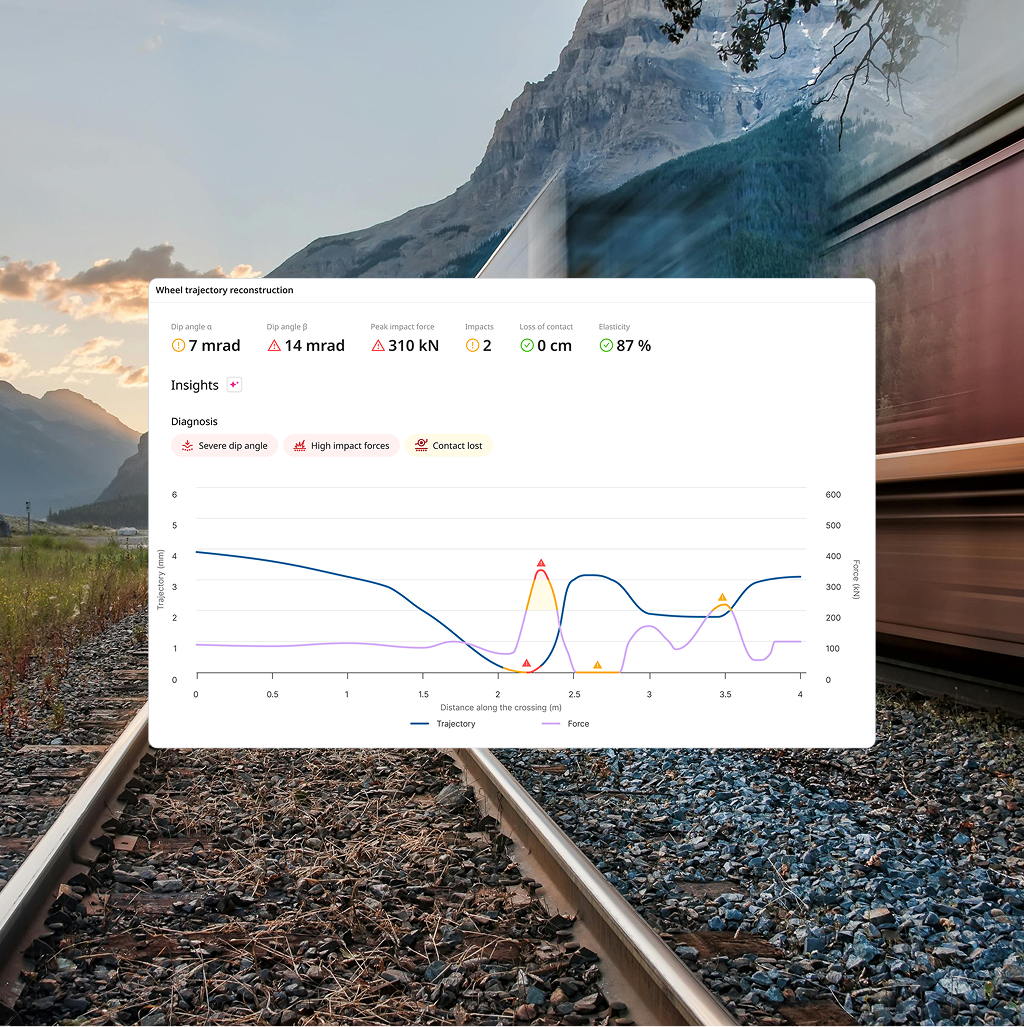

Frog Health Monitoring

Monitors acceleration and displacement in the crossing area. Detects early degradation, predicts remaining useful life, and helps extend asset lifetimes.

Watch videoTrackbed Health Monitoring

Trackbed Health Monitoring

Continuously measures vertical displacement under train load. Detects voiding and settlement early, enabling targeted tamping and avoiding adjacent component damage.

Watch videoPoint Machine & Locking Health Monitoring

Point Machine & Locking Health Monitoring

Combines electric current, pressure, vibration, and weather data to track mechanical wear and control system performance of point operating equipment. Identifies root causes and supports timely interventions.

Watch videoFeatures

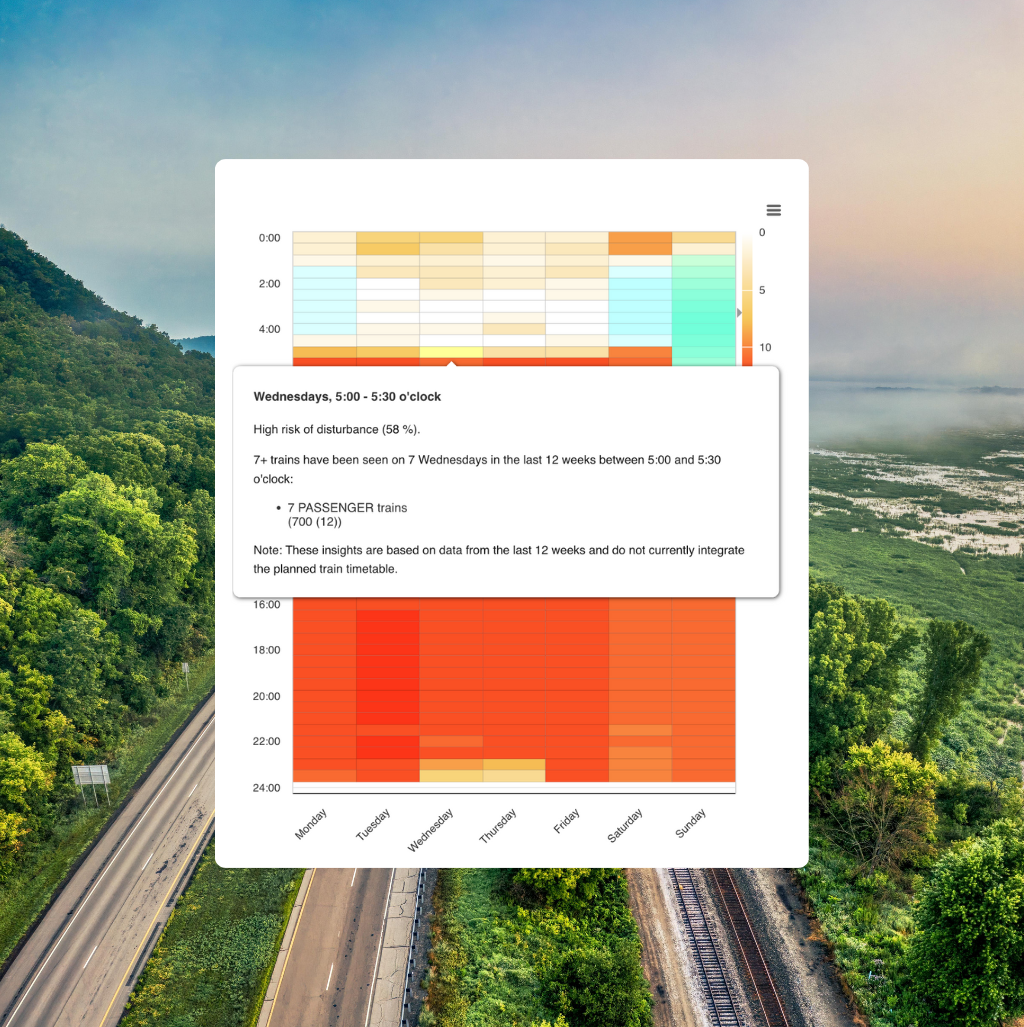

Reduce disruption

Catch failures early and schedule interventions before they cause unplanned downtime or speed restrictions.

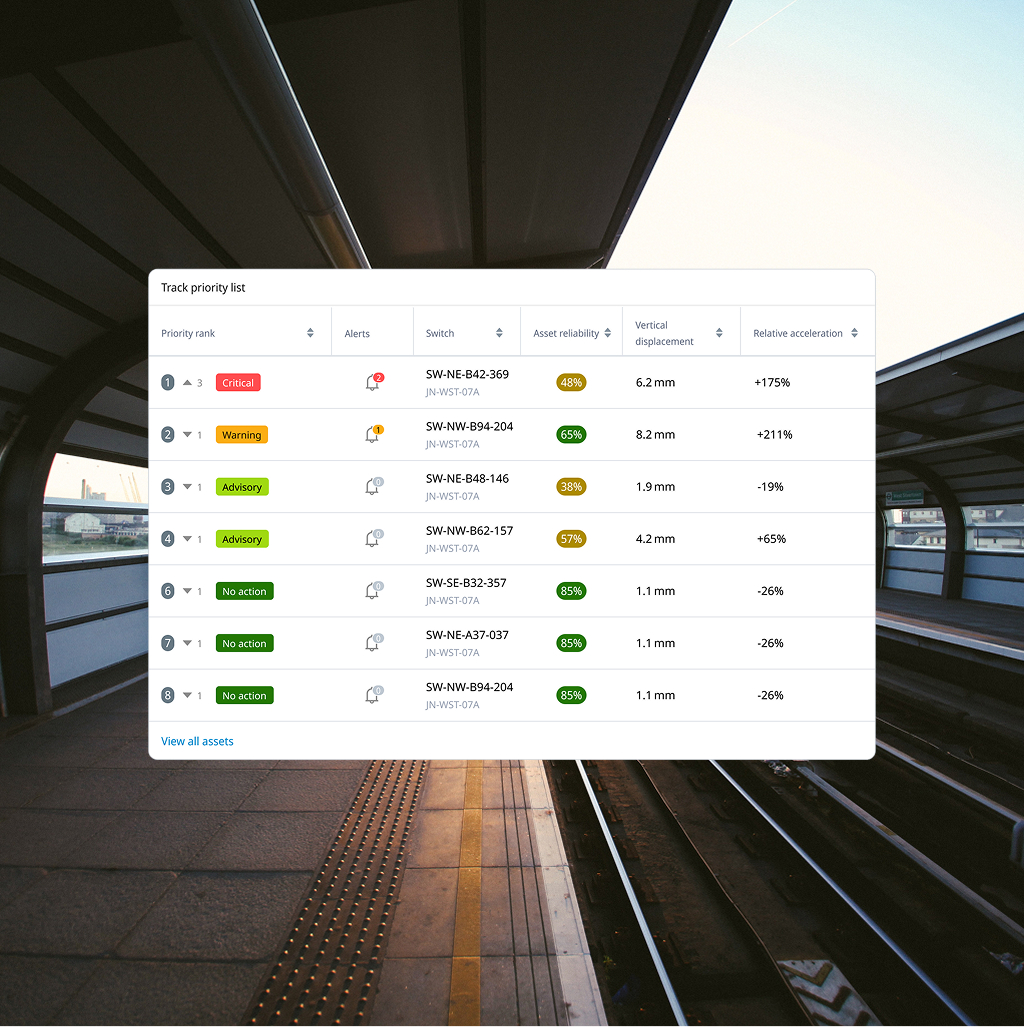

Lower cost

Target the right switch, at the right time. Extend component life and reduce unnecessary maintenance.

Increase safety

Reduce time in the field. Enable more scheduled, daytime work and fewer emergency responses.

Improve decision-making

Gain real-time visibility and Al-driven insight into switch condition, usage, and performance.

- Reduce disruption

- Lower cost

- Increase safety

- Improve decision-making

Hardware

IloT sensors installed in under 15 minutes, with 5+ years battery life

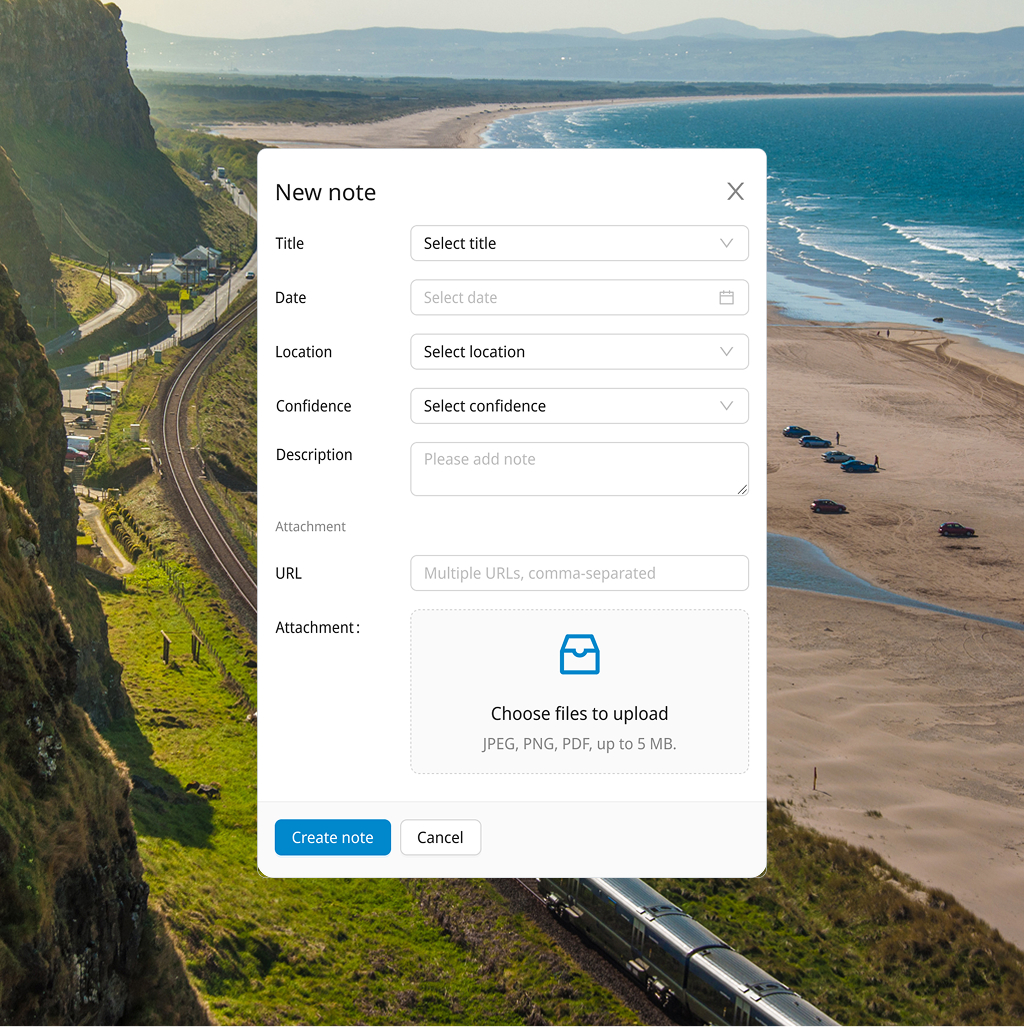

Software

Cloud-based dashboard for monitoring, alerts, and planning

Al Core

Trained on 500M+ train traces across 10+ countries, 13 AI models

Security

ISO 27001-compliant; hosted in Germany; fully encrypted

Case Studies

Look at possible applications

Proven Impact in the Field

See how leading rail operators are using KONUX to boost reliability, efficiency, and performance.